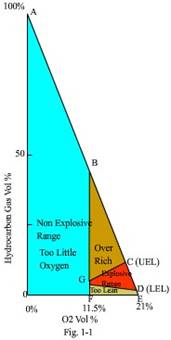

Explosive Range

We

have to consider the tank atmosphere which. may contain any one of three gases

such as hydrocarbon gas, inert gas and fresh air.

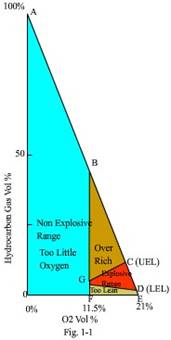

Then

we have to pay attention to hydrocarbon gas and oxygen in fresh air which are

necessary to explosion. As oxygen content in fresh air is approx. 21 % we can

draw the graph shown in Fig. 1-1 which shows hydrocarbon gas with the range

from 0% to 100% in the vertical axis and oxygen content with the range from 0%

to 21% in the horizontal axis.

Point

"A" in Fig. 1-1 means the tank atmosphere which consists of 100%

hydrocarbon gas.

Point

"O" means the tank atmosphere which consists of 100% inert gas.

Point

"E" means the tank atmosphere which consists of 21 % oxygen.

From

the above we can consider any kind of tank atmosphere which consists of three

gaseous bodies such as hydrocarbon, inert gas and fresh air according to this

Fig. 1-1. This means, in other words,,that the tank atmosphere lies within the

triangle AOE.

Explosive Range, UEL and LEL

(also termed as UFL and LFL)

Under

the tank atmosphere which consists of hydrocarbon gas, inert gas and fresh air,

the range of mixture of oxygen and hydrocarbon gas which can be ignited by an

external ignition source is called the "Explosive

Range" or "Flammable Range".

Volume

percentage of hydrocarbon gas and oxygen are called "Oxygen content"

and "Hydrocarbon gas content".

This

explosive range is shown in Fig. 1-1, the area surrounded by points CGD (Flammable

envelope).

The

highest point of hydrocarbon and oxygen mixture gas in this area is called the

Upper Explosive Level (UEL) and the lowest point is called the Lower Explosive

Level (LEL).

Non-Flammable Range

Fig.

1-1

No

ignition occurs in the area which is outside the explosive range because of

inadequate mixture of hydrocarbon gas and oxygen. This area is called the

"Non-Flammable Range" or "Non-Explosive Range".

This area is shown in Fig. 1-1

A.

Too Little Oxygen

Assuming

that the oxygen content is less than the point G (less than 11.5%) no explosion

can occur even regardless hydrocarbon gas content in a tank. So we call this

area surrounded by points AOFB as Too Little Oxygen condition.

The

purpose of I.G.S. installation and the main points of I.G.S. operation is to

ensure the tank atmosphere is in the Too Little Oxygen condition.

B.

Over Rich and Too Lean

Compared

with the volume of oxygen, the volume of hydrocarbon gas is too much in the

area surrounded by points BGC and no explosion occurs in this area so referred

to as the Over Rich condition. On the other hand, the area surrounded by points

GFED shows that the volume of hydrocarbon gas is too little compared with the

volume of oxygen and no explosion occurs in this area called the Too Lean condition.

How to Use the Explosive Range

Diagram

The

tank atmosphere which is not supplied with inert gas is to be considered on the

line AE (Fig. 1-1) and it may come into the explosive range (Line CD). The

vessel which is installed with I.G.S. can keep the tank atmosphere within the

Too Little Oxygen condition by supplying inert gas.

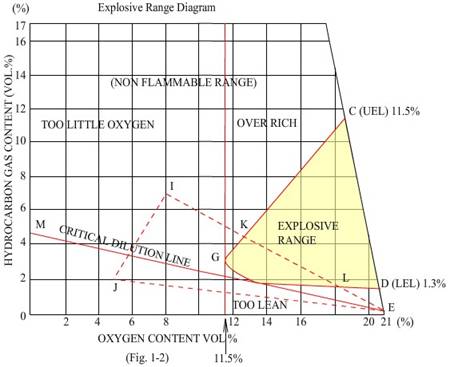

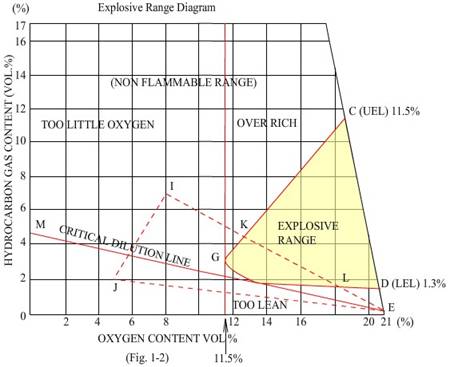

The

hydrocarbon composition of crude oil is various between the different grade and

there is only a small variation in their explosion range. Therefore, in order

to have the desired margin of safety, the point UEL is taken as 11.5% by

hydrocarbon, LEL is 1.3% and the point of too little oxygen is 11.5% so we can

draw boundary of the explosive range as shown in Fig. 1-2.

Keep tank atmosphere less than 8% of oxygen

content

Fig.

1-2. is a magnified view of Fig. 1-1. (Area of hydrocarbon content from 0% to

17%).

When

we want to know what the tank atmosphere condition is, we find it out by

plotting oxygen and hydrocarbon content as in Fig. 1-2.

Assuming

at the end of tank washing, a cargo tank atomosphere is measured and found to

contain 7% hydrocarbon and 8% oxygen. Plotted on the Explosive Range Diagram

this is point (I). If gas freeing was then carried out, the hydrocarbon content

would decrease and the oxygen content increase, while passing along line IE.

However, on reaching point K on the flammability envelope the tank atomosphere

enters the explosive range and remains in this condition to point L. In order

to avoid such a condition, it is therefore necessary to purge with Inert Gas

before gas freeing with air. Purging the tank atomosphere with good quality

Inert Gas will reduce the oxygen content as well as reducing the hydrocarbon

content, passing along line IJ. Once at J i.e. 2% hydrocarbon and 5% of oxygen,

the gas freeing operation can begin and the addition of air will them keep the

tank atomosphere outside the explosive range by moving along line JE.

If we

draw a line from point E to the tangent point of explosive range so we get the

line EM which is called the Critical Dilution Line. Since the tank atmosphere

comes below the Critical Dilution Line there is no possibility of explosion

when we supply fresh air into the tanks.

We

must therefore carry out gas freeing after confirmation of the tank atmosphere

that it is below the Critical Dilution Line after measuring the tank oxygen

content and hydrocarbon content.

COMPONENTS OF INERT GAS

The

exhaust gas which is produced by the boiler is called Flue Gas. In the

scrubber, the flue gas is cleaned and cooled and with an oxygen content less

than 5% is known as Inert Gas. The equipment which supplies the Inert Gas to

the cargo tanks is known as the Inert Gas System.

Automatic

Combustion Control (ACC) is the equipment which controls the rate of fuel oil

and fresh air automatically in the combustion process.

This

equipment should be kept in proper operating condition in order to ensure the

supply of Inert Gas of the desired quality. When operating cargo or ballast

pumps, communication with the engine room must be maintained. This is particularly

important when stopping or reducing the speed of cargo pumps, so that the

combustion control operation must be checked to ensure Inert Gas oxygen content

is maintained below 5%.

Components

of Inert Gas (Fig. 1-3)

Flue Gas Inert

Gas

Temperature 300-400 Sea Water Temp. +5 C

Oxygen 2-5% 2-5%

Carbonic

acid gas 13-15% 13-15%

Sulphur 0.3% 0.03%

Vapour 250 mg/ml (max) 8 mg/ml (max)

Mist 95%

of elimination

Nitrogen Balance Balance

TANK

ATMOSPHERE AND INERT GAS

Discharging

Cargo (Fig.1-4)

Ullage space in a cargo tank before discharging

cargo is generally OVER RICH because of the high content of hydrocarbon gas.

Reference Fig. 1-4. Assume H is a typical content of

oxygen and hydrocarbon before discharge begins.

Consider two conditions:-

o

Discharging without Inert Gas

o

Discharging with Inert Gas

In the first case, the hydrocarbon content will

decrease and the oxygen content increase along the line HE, when at the end of

discharge of, that tank, the atmosphere could be flammable.

In the second case, both hydrocarbon and oxygen

contents will decrease towards J and the tank atmosphere will therefore remain

outside the explosive range.

On Passage

(Fig. 1-4)

In the absence of positive pressure on a cargo tank

either loaded or in ballast air may enter through the breather valve due to

climatic changes.

Loaded Passage

On the loaded passage, hydrocarbon gases likely to

vaporize so that the ullage space is generally in an OVER RICH condition.

However, with air coming in through the breather valve, the hydrocarbon content

will be reduced and could possibly reach flammable levels. With Inert Gas

protection this can be avoided by maintaining a positive pressure throughout

the loaded passage.

Ballast

Passage

Cargo tank as supplied with good quality inert gas

while discharging cargo are in the TOO LITTLE OXYGEN condition when the vessel

leaves port. If tanks are kept under positive pressure throughout the ballast

passage, the tank atmosphere will not enter the explosive range. Therefore, it

is necessary to record the tank pressure regularly and if necessary, top off

with good quality inert gas.

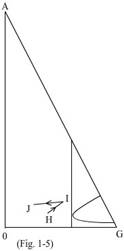

Tank Cleaning

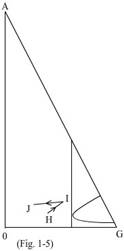

(Fig. 1-5)

If good quality Inert Gas i.e., below 5% of OXYGEN

is supplied when discharging cargo, the tank atmosphere will be inert and

therefore ready for tank cleaning. However, positive pressure needs to have

been maintained between the discharging and tank cleaning. If not, air car

enter the cargo tanks thereby increasing the Oxygen content along line HI.

Before starting tank cleaning, oxygen measurements should be made to confirm it

is below 8%. If over 8%, then purging is necessary to reduce the oxygen content

from I to J. Fig. 1-5

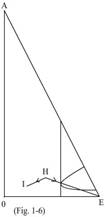

Deballasting.

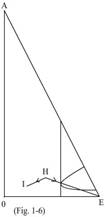

(Dirty – deballasting Heavy weather ballast) (Fig. 1-6)

Assuming H is point representing a typical tank

atmosphere prior to deballasting. If NO inert gas supplied during deballasting,

then the tank atmosphere will go along line HE, passing through the explosive

range. If however, Inert Gas is supplied during this operation then the tank

atmosphere moves along line HI and therefore outside the flammable envelope. Fig.

1-6

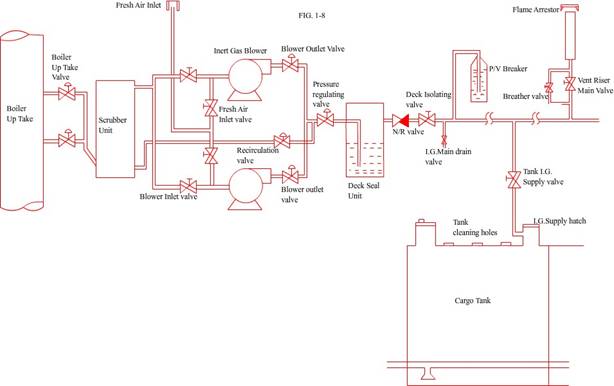

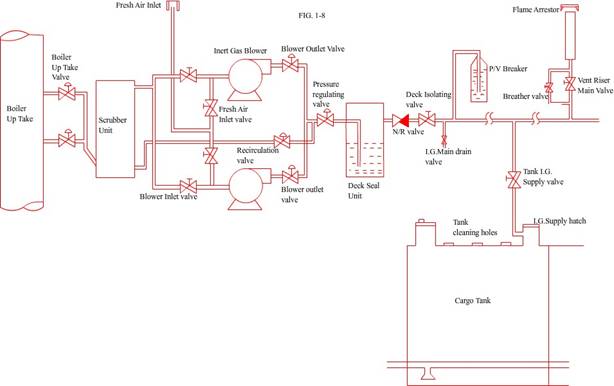

OUTLINE OF INERT GAS SYSTEM

Basic

Equipmentof Inert Gas System

I.G.S

equipment is provided with certain safety features and is designed to clean,

cool and supply flue gas under pressure and of satisfactory quality for

delivery to the cargo tanks. I.G.S. consists of the following.

Flue

gas generated from the boiler flows through the Boiler Up-take Valve and into

the Scrubber. There, the gas is cooled down and washed by sea water supplied by

the Scrubber Water Pump. Leaving the Scrubber the gas passes through the

Demister where water droplets are moved before entering the Blower suction. On

the discharge side of the Blower, oxygen content and temperature of the flue

gas are monitored. High oxygen content and high temperature activate alarms.

Inert

Gas from the blower flows in to the Deck Seal through Inert Gas Pressure

Regulating Valve. Main line pressure is

automatically controled to keep desired pressure constant. Excessive pressure

is avoided by the Inert Gas Pressure Regulating Valve working in conjunction

with the Recirculation Valve.

The

Deck Seal isolates the boiler up-take from the deck line by using sea water and

to prevent the backflow of the hydrocarbon gas. Inert Gas from the deck seal

flows into the deck supply line through the Non-retum Valve and Deck Isolating

Valve and then enters each tank through the Inert Gas Supply Valve (some

vessels do not have individual valves). The Inert Gas System can also be used

for Gas Freeing by opening the Fresh Air Inlet Valve.

The

P/V breaker is installed to protect the cargo tanks from excessive pressure or

vacuum.

Functions of the Inert Gas System Unit

BOILER

UP-TAKE VALVE

Flue

Gas generated by the boiler flows into the Scrubber Unit through the Up-Take

valve. This valve is opened by remote control on Blower start up and when the

Blower stops this valve has to be closed in order to avoid Flue Gas entering

the Scrubber Unit.

SCRUBBER

UNIT

This

is installed to clean and cool the flue gas and to reduce the sulfur dioxide

(SO2 ) from the flue gas. The temperature and composition of the flue gas is

schown in Components of Inert Gas (Fig. 1-3).

DEMISTER

The

demister is provided to remove water droplets contained in the inert gas which

have passed through the scrubber. Since the inert gas is cooled and cleaned at

the scrubber, the gas at the scrubber outlet inevitably contains water droplets

as a result of its direct contact with the sea water used for cleaning it and

could thus overload the blower and damage and increase corrosion on the blower

impellers.

BLOWER

Total

blower capacity is more than 125% of total cargo pumps capacity. And

combination of two blowers is;-

o

two blowers together giving 125% (i.e. 62.5% each) of total cargo pump

capacity. Thus two blowers must be used during normal cargo discharging

o

one blower having 125% capacity plus one standby/ auxiliary with either

30/ 60/ 125% of total cargo pump capacity

DECK

SEAL UNIT

The

IGS connects the boiler up-take indirectly with the cargo oil tanks, and while

the system is not in operation, the backflow of the oil vapour under pressure

from the cargo tanks must be protected against. The Deck Seal is provided for

this purpose.

RECIRCULATION

LINE

This

allows the blower to operate when the pressure.regulating valve is being

closed. Gas flows back through this line to the Scrubber and thus avoids

pressure built up on the discharge side of the blower.

P/V

(Pressure Vacuum) BREAKER

Under

normal conditions, the Breather Valve controls the cargo tank pressure/vacuum

automatically when the I.G.S. is off. As a back-up safety device, a

Pressure/Vacuum Breaker is fitted to the deck main piping and is designed to

release pressure from this piping and cargo tanks to atmosphere in the event

that the Breather Valve capacity is exceeded while operating the I.G.S.

The

P/V Breaker does not have any moving parts and is filled to be required level

by oil or fresh water containing an antifreeze solution.

Detectors

OXYGEN

ANALIZER (FIXED TYPE)

This

contineously measures the oxygen content of the flue gas on the discharge side

of the blowers. Oxygen content is effected by the combustion efficiency of the

Boiler, or the proportion of surplus air. The alarm lamp flickers when the

oxygen content is more than 5% and the alarm buzzer sounds when the content is

more than 8%.

THERMOMETER

This

is fitted on the blower outlet and continuously measure the temperature of the

inert gas. The temperature of the inert gas at the blower suction is normally

5C higher than the scrubber water but it is increased while passing through the

blower. The temperature alarm lamp flickers at 60C and the blower is tripped at

65C.

PRESSURE

DETECTOR

This

is fitted in order to measure the pressure in the main inert gas line common

with all cargo tanks. The pressure at the outlet of the deck seal is detected

by the pressure transmitter, which operates the pressure switch in the cargo

control room panel.

TANK

INERT GAS SUPPLY VALVE and VENT RISER MAIN VALVE

When

using the Inert Gas System, Tank Supply Valve (if fitted) should be open and

the Vent Riser Main Valve should be closed.

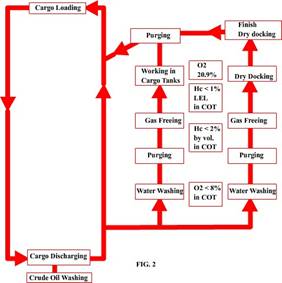

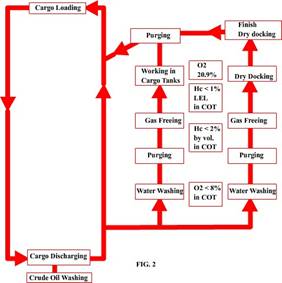

OPERATION AND APPLICATION OF INERT GAS SYSTEM

One

cycle of tanker operation is as shown in Fig. 2.

Tank

atmosphere is safe from explosion with an O2 content of below 8%.

The

alarm buzzer of the O2 content analyzer will sound when the O2 content is more

than 8% and the supply to the deck seal will stop and the recirculation valve

will open. However, in normal operation, O2 content of supplied I.G. should be

below 5%.

Tank

atmosphere is most important therefore measurement of O2 content and

Hydrocarbon gas should be carried out with strict attention according to

sections.

TANKER

OPERATION/ONE CYCLE

GENERAL

OPERATION AND PRECAUTIONS

Generally,

operating procedure for I.G.S. is as undermentioned.

However,

operation of I.G.S. should be considered in conjunction with individual maker's

instruction manuals.

General Operating Procedure

|

Starting procedure

|

General check & confirmation

|

|

Communication with engine department

|

(1) a.Inform

engineers when system will be required. (2hrs notice)

b.Check

: Possibility of soot blowing before starting the I.G.S.

c.Confirming

generater capacity/readiness for operating blower and scrubber water pump.

|

|

Scrubber

water pump START (at least half hour before starting system – dpending on

Manufacturer)

|

(2) a.

Confirm Cooling water supply.

b.Check

: Flow rate by flow meter or pressure gauge.

c.Confirm

Scrubber drainage by visual inspection.

|

|

O2 Analyzer switch ON

|

(3) a. Check

: Zero adjust and Span adjust.

Confirm

: Supply water.

b. A

characteristic of the magnetic 02 analyzer is that it reaches normal measurement condition in about 2

hours after being switched on.

Therefore,

it should be switched on at least 3 hours before starting the I,G.S.

|

|

Control panel switch ON

|

(4) a.

Lamp and buzzer test should be carried out to confirm electric circuit is operating correctly

|

|

CONFIRM

|

(5) a. Open

: Scrubber drain valve

Demister

drain valve (Where appropriate)

Blower

drain valve

Deck

seal drain valve

b. Confirm

: Water level in deck seal unit.

Water

supply to deck seal unit.

|

|

Fresh air inlet valve CLOSED

|

(6) a. It

should always be closed except when gasfreeing.

|

|

I.G. supply valve OPEN

|

(7) a.

Confirm : I.G. supply valve for individual tanks (if fitted).

b.Closed

tank hatches, ullage ports, I.G. supply hatches and tank cleaning ports.

|

|

Deck isolating valve OPEN

|

(8) --

|

|

Blower inlet valve OPEN

|

(9)

|

|

Boiler up-take valve OPEN

|

(10) a. Confirm

Opened completely.

b. Confirm

Seal air valve closed.

|

|

No. 1 (or No.2) blower START

|

(11) a. Check

Blower operating normally.

b.

Confirm Indication of ammeter normally.

c.When

using two blowers, the 2nd blower should be started 30 seconds after the 1st blower is

started.

|

|

Blower outlet valve OPEN

|

(12) a.It

should be opened after blower is started.

b.Confirm

: Pressure attained.

On blower start up, I.G. is recirculated

automatically through the scrubber and recirculation line.

|

|

Pressure

regulating valve OPEN

|

(13) a. It

should be gradually opened.

b.Check

: Blower dischargeO2 content and temperature.

c.Bringing

up to required pressure.

|

|

INERTING

|

(14) Inert

Gas will be supplied into the tanks.

|

B. Stopping procedure GeneralGeneral check & confirmation

|

INFORM Engine department

|

(1)- - -

|

|

Blower STOP

|

(2)- - -

|

|

Valves

of I.G. plant CLOSE

|

(3) a.

Boiler up-take valve

b.

Blower inlet valve

c. Blower

outlet valve

d. Pressure

regulating valve

|

|

Deck

isolating valve CLOSE

|

(4) - - -

|

|

Deck

seal water level CONFIRM

|

(5) a.

Confirm: By observing water level through sight glass.

|

|

Cooling

down of scrubber CONFIRM

|

(6) a. Keep

scrubber pump running after system shut down for about 30 minutes.

|

|

Scrubber

water pump STOP

|

(7) a.

Confirm Water seal level in scrubber by visual inspection through sight glass.

|

|

O2

content Analyzer STOP

|

8)- - -

|

|

Control

panel switch OFF

|

9)- - -

|

General Precautions

1) Do

not start up the I.G.S. without first informing the engine control room. Keep

engine control room informed of start/stop requirements.

2) Inert

gas supply valve of each cargo tank should be kept open at all times except gas

freeing, tank repairing.

3) I.G.

supply valves should not be operated without permission of the duty officer (

it generally has an arrangement to lock the valves – key with duty officer). The

duty officer must pay careful attention to ensure the I.G. supply valves are

open before any cargo movement either by cargo pump or gravity.

It is important to be aware to recognize that

if I.G. supply valve is CLOSED and any cargo movement made, structural damage

could occur.

4) The

fresh air inlet valve must be kept closed at all times except when the I.G.

blower is being used for gas freeing.

5) Seal

water of deck seal unit should be supplied at all times whether the I.G.S. is

operating or not, to ensure the seal water is kept at the proper level. The

supply has one dedicated pump and a back up.

6)

The operator must confirm that the outlet valve of the I.G. blower is closed

before starting the I.G. blower.

(The

blower outlet valve will automatically be opened on certain maker's systems.)

7) Before

operating the I.G.S., the Supply of water into the Scrubber should be confirmed

by visual checking of the pressure gauge and/or flow meter. Blocked spray nozzles can result in

indicating the correct pressure but not the required flow. It is therefore

important to keep the spray nozzles clean.

8) The

liquid of the P/V breaker must be kept at a proper level at all times. The

gauge glass should have spring loaded valves.

9)

Prior starting the IGS the O2 analyser should be callibrated with Nitrogen.

While

operating the I.G.S., the duty engineer must check the flxed O2 analyzer by means

of comparing it with a measurement made by portable O2 meter from the blower

outlet.

10) The

impeller of the I.G. blower should be washed with fresh water as soon as possible

after each time the system has been used.

(This

is to prevent corrosion of the impeller and wash away soot deposits which might

cause imbalance of the impeller and excessive vibration.)

11)

The I.G. blower should be started by operating the switch installed beside the

blower.

12) There

are cases when the temperature of the blower outlet will rise during

recirculation of I.G.

------------------------------------------------------------------------------------------------------------------------------------------